The paper presents techniques for semi-trailer structures that source with the application of extremely good management systems. Also, it offers examples of carried out solutions based on quality management thru manufacturing approaches control with special emphasis on special techniques ensuing in acquiring a product that accomplishes user requirements.

There are many factors that affect the quality of a welded joint. In addition to the technologies used, process parameters and materials are also affected by the quality of the welder. Therefore, the resource operation is a custom operation. The need to attach the factors of a vehicle semi-trailer is due to the fact that it can not be realized inside the monolith. Motivations for dividing the semi-trailer into elements, amongst others: the overall performance of numerous materials due to working conditions, the general overall performance of numerous tasks inside the running technique of the semi-trailer construction, compensation of relative deformations. Consequently, it is important to ensure high quality of welded connection. Since the source link is affected by many attributes, we classify the source system as a special process.

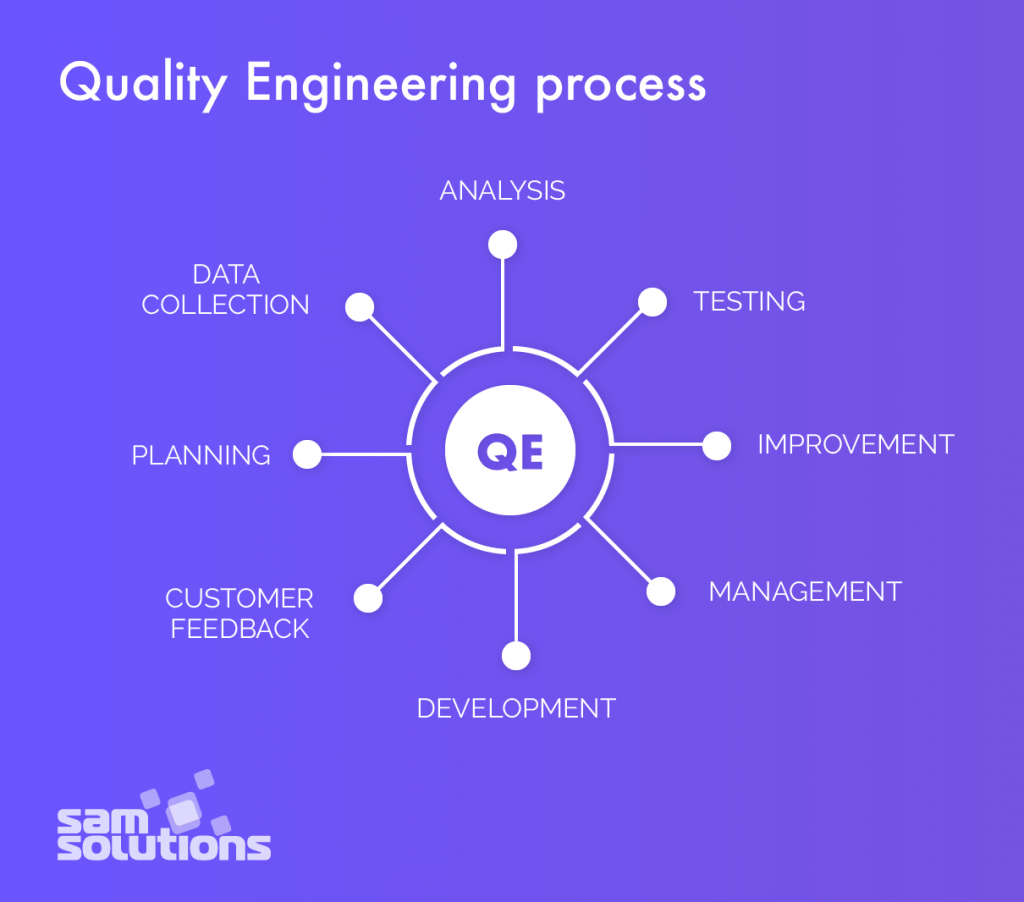

Determining high-quality necessities for welding techniques is crucial because the nice of those strategies cannot be without problems verified. As such, they are handled as special strategies. Quality cannot be controlled inside the product but need to be established with it. The sources of some of the critical load-bearing elements of a semi-trailer covering an extended period had been tested. The research changed into analyzed by way of welders with diverse professional experiences. State scale turned into used to decide the numerical value of the pleasant adequacy. Qualification evaluation consists of welder qualifications, expert practice, finished training, and seniority in factory-generating trailers. For building manufacturers, where the main process is a welding process, in addition to the requirements of the ISO 9001 standard, it is far the necessities of one of the ISO 3834 pages of the first-rate warranty concepts in unique processing. Depending on the performance issue and the use of a welded structure, the manufacturer must meet the necessities of one of the ISO 3834 pages.

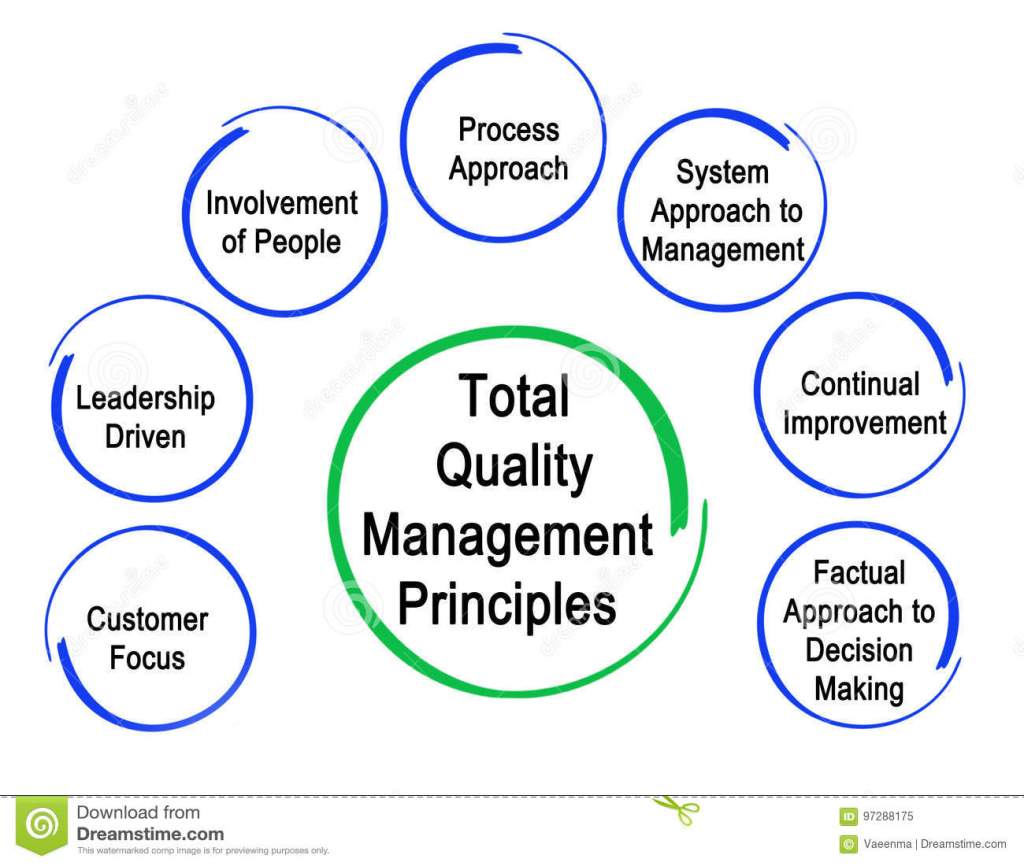

Meeting the necessities of ISO 9001, ISO 3834, ISO / TR 3834-6 standards permits control in the business enterprise and gives welding necessities to make certain the satisfactory of the welding process. Appropriately developed approaches and commands allow for higher inspection, facilitate resource control, make certain compliance with customer necessities, and audit the high-quality of the product. In summary, the improvement of welding technology instructions creates the essential foundations, but they can not ensure that the assets made according to them are the requirements set for them handiest the Quality Management System provides the possibility to make certain high best in unique processes.